Electronics Fabrication & Repair Lab

Our vast parts division is stocked floor to ceiling with more than 10,000 ready-to-ship parts.The

Phantom Technologies cleaning area features a two-part cleaning station and ESD-controlled blow-off and incubation-type drying oven to ensure the removal of all traces of solvent from your component.

Our custom-harness assembly area features many variations of ultra high-flex cabling and industrial connectors and all work is performed by qualified soldering specialists.

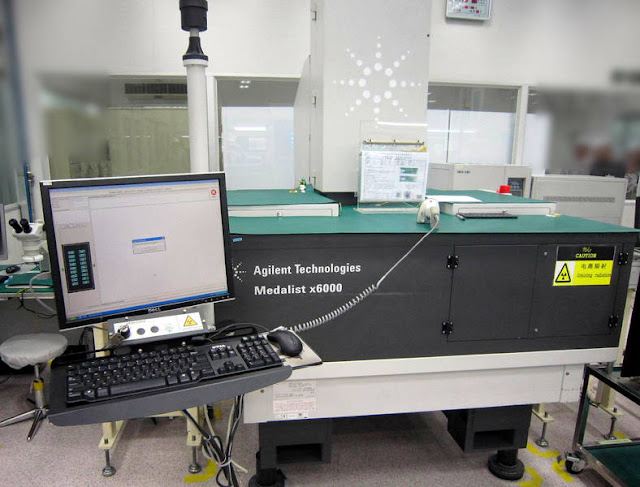

Instrumentation Laboratory

This facility houses ten measurement and computer data acquisition workstations that can accommodate up to 18 technicians at a time. There are facilities for measuring and controlling pressure, temperature, heat transfer, strain, vibration, fluid velocity and flow rate, and material properties. The lab components of MECH 322 Instrumentation and other mechanical systems are taught in this facility.

This facility is for capstone design projects and laboratory experiments in mechatronics, controls, and vibrations

Machine Shop

Phantom Technologies is fully equipped with Advance Machine Shop Containing High Tech VMCs, CNCs, pressing and laser cutting machine

Micro-Electronics Fabrication Lab (Clean-room Facility)

Micro-Electronic Fabrication Lab (MEFL), the clean room facility (CRF) is an integral part of the MEFL. The CRF consists of a 300 sq. ft. class 100 room, with an adjacent 900 sq.ft. class 1000 room with humidity and temperature control.The class 100 room contains a chemical process station, tube furnace capable of 1200˚C , two ovens, a muffle furnace capable of 800˚C , a thermal evaporator with diffusion pump capable of 0.1 micro-Torr, an e-beam evaporator with a turbomolecular pump having vacuum capability of .01 micro-Torr, two mask aligners capable of 2 microns resolution, reactive ion etch for dry patterning, and photoresist system for photoresist deposition. An 18 Mohm deionized water system provides high quality water required in semiconductor processing.

The class 1000 room was recently constructed to expand our clean facility. It now contains a plasma-assisted chemical deposition system, three-zone tube furnace capable of1200C ˚, four point probe system to test resistivity of wafers, ellipsometer, ozone cleaning system, rapid thermal anneal, e-beam evaporator, 3 target sputter system, reactive ion etch system and microwave plasma deposition system. More equipment will be added in the near future.

An adjacent room contains a steel-jar evaporator with capability for e-beam and R.F. magnetron sputtering, another system for D.C. magnetron sputtering, and a three targets sputter system.

Measurement facilities include optical microscopes, a sub-micron probe station, current-voltage-temperature, capacitance-voltage-temperature, deep level transient spectroscopy, quasi-static C-V, cryogenic systems, and a variety of meters for measuring resistance, current, capacitance and voltage.

Mainframe Computer System

Phantom Technologies has it's own state of the art mainframe computer system for high speed data processing and complicated simulations and calculations of the mechatronic system design.

We have experienced team of experts in various disciplines such as Computational Biology, Computational Fluid Dynamics, Computational Materials Science, Aerospace, Information Security, Seismic Data Processing, Reservoir Simulations, Weather Forecasting, High Speed Rendering, and High Performance Analysis.

Phantom PCB is established by Source Bio Science group as the PCB business unit. It is consisted of 3 units located within the facility.The main products focus on 2 to 22 layers bare PCB and HDI PCB. The strength of Phantom lies in our full study of what the customers' needs and the stringent quality requirement. We then provide the products with the core value of high reliability, on time delivery and responsive after-sale service. Environment protection is also considered carefully in Phantom. We carefully control the wastage from every process of production, and we follow the international regulation to avoid the electronic manufacturing effects against the earth.

Phantom is your trusted electronic manufacturing services provider. Backed by more than 5 years of global experience , we continue to drive to become one of the leading suppliers in the EMS industry. We vertically integrate our factories wide range of capabilities, know-how and supply chain management to meet our customer most stringent requirements. We offer our customers an all-in one solution from PCB, PCBA, LCM to complete Box-Build and System Integration. Specializing in the fields of computer peripherals, communications, medical, automotive, automation and industrial electronics enterprise, we have partnered with many Tier-1 brand names from North America, Europe and Asia.

0 comments:

Post a Comment